We are now NAAD UK approved.

Lex Hygiene is a NAAD UK approved air and grease duct cleaning company. Our staff are fully qualified and trained to approved GHT (Grease Hygiene Technician) standards.

Contact Lex Hygiene today to find out how we can help you and your business stay safe and legal this year.

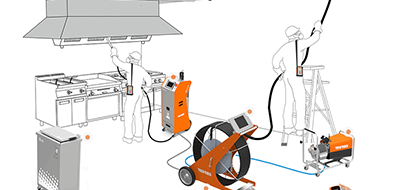

Grease Duct

Cleaning

find out more

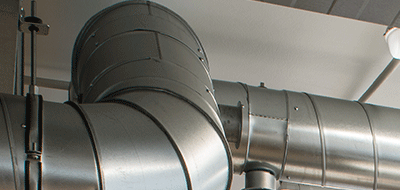

Air Duct

Cleaning

find out more

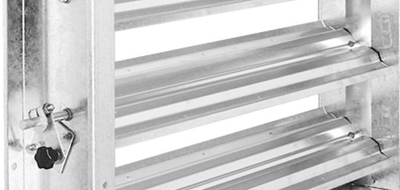

Fire Damper

Testing

find out more

Commercial Windows

Cleaning

find out more

Commercial

Cleaning

find out more

3 Stage

Cleaning

find out more

Fogging

Service

find out more

Jet Washing

Cleaning

find out more

OZOAIR

Cleaning

find out more

Exterior

Cleaning

find out more

CONTACT US

Get In Touch

Please use the Contact Form opposite to get in touch and tell us something about your requirements.

Alternatively, you can email us directly at

info@lexhygiene.co.uk

Or call us on

01302 301401

WHAT OUR CLIENTS SAY

"The guys were spot on, very happy and look forward to working with you in the future"

Stuart Allen / General Manager, The Hardwick Inn

JUST SOME OF OUR HAPPY OUR CLIENTS